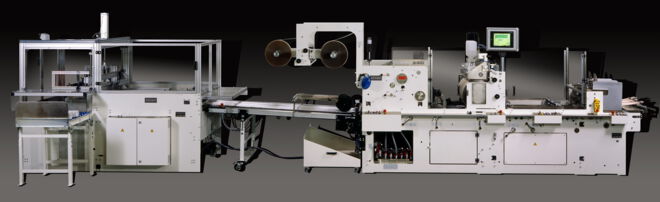

The basic machine includes:

- New servo technology for the timed belt feeder

- All cylinders are driven directly by servo motors

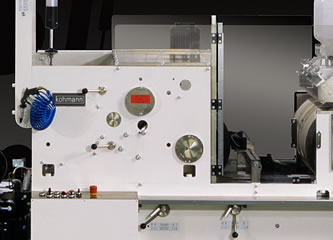

- Glue unit with separate drive

- Input and automatic adjustment of carton relevant dates are made via a large color operator interface panel

- Storage of more than 4000 carton data for repeat orders is possible

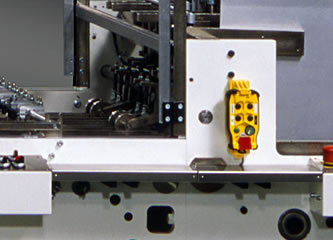

- Advance and retard of the stereo cylinder to the carton is carried out from the operator side

- Right/Left adjustment of the stereo cylinder is carried out from the operator side even with 2-stream operation

- Max. 4-up operation possible

- Larger size ranges for 2-up and 3-up operation

- Micro-fine adjustments of board to glue and foil position whilst machine is running

- Online maintenance via modem worldwide

- Up to 2 streams possible

- Operator friendly

- High production quality

- Minimal change-over times due to computer control

- Computer-driven production control system with automatic adjustment

- Maintenance free drive concept

- The machine is accessible for adjustment and maintenance work

- Infenitely variable delivery speed by separate drive

- All-purpose due to the ability to add extra modular devices

Highlights

Window styles

Gallery

Technical Specifications

Adjustment range, single stream operation |

|||

| F-1120 | |||

| min. | max. | ||

| Blank length | mm | 100 | 1240 |

| in | 3 15/16 | 48 13/16 | |

| Blank width | mm | 80 | 1120 |

| in | 3 1/8 | 44 1/10 | |

| Film length | mm | 60 | 800 |

| in | 2 3/8 | 31 1/2 | |

| Film width | mm | 30 | 840 |

| in | 1 3/16 | 33 | |

| Power | |||

| Total power consumption | 32 kW | ||

Adjustment range, double stream operation |

|||

| F-1120 | |||

| Blank width | mm | 545 | |

| in | 21 1/2 | ||

| Film width | depending on blank position | ||

| Film thickness | 20 - 350 microns | ||

Output figures |

|||

| when using belt lifter system | 1-stream max. pcs/min. |

2-stream max. pcs/min. |

|

| 1-up operation, blanks over 610 mm |

200 | 400 | |

| 2-up operation, blanks under 610 mm |

400 | 800 | |

| 3-up operation, blanks under 385 mm |

600 | 1200 | |

| 4-up operation, blanks under 270 mm |

over 600 | over 1200 | |

| 3-stream operation | values must be multiplied accordingly | ||